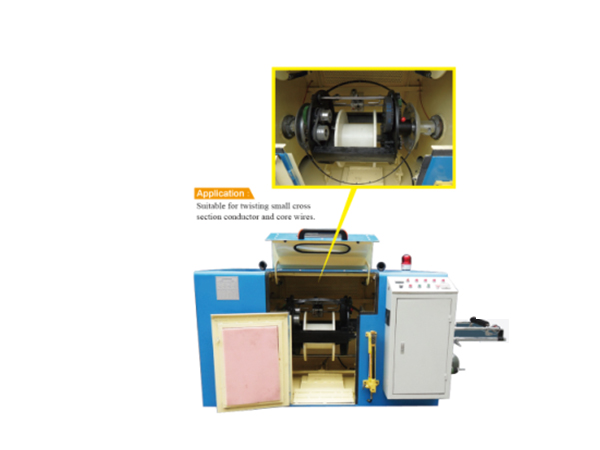

尼龍護套擠出生産(chǎn)線(xiàn)

Nylon sheathed extrusion production line

設備特性

Device characteristics

·适應于各類尼龍護套電(diàn)線(xiàn)擠出

Suitable for all kinds of nylon sheath wires extrusion

·螺杆機筒:無錫擠出機,采用(yòng)日本新(xīn)結構設計,并根據不同擠出工(gōng)藝要求,特設加強結構,以适應各類尼龍等的擠出。

Screw barrel: using the latest Japanese structure design, according to the different extrusion process requirement, AD hoc strengthening structure, so as to adapt to all kinds of NYLON extrusion。

·機頭:尼龍專用(yòng)機頭

Nose: nylon special head

·加熱冷卻系統:配合螺杆機筒的特殊設計,本機配備獨特的加熱及冷卻系統,以滿足不同膠料的精(jīng)密擠出的要求。

Heating cooling system: cooperated with special designed screw barrel, this machine is equipped with unique heating cooling system, to meet the requirements of different rubber extrusion.

擠出附機:本機可(kě)根據不同的工(gōng)藝要求,可(kě)選配合适的鋪機(30、35、40等),更換機頭和螺杆後即可(kě)産(chǎn)生尼龍護套線(xiàn),并可(kě)滿足單注滌、雙注滌及雙層共擠等不同工(gōng)藝要求。

Attached extrusion machine: this machine can according to different technical requirements, it can be equipped with suitable accessory extruder(30, 35 40, etc.) after the replacement of the nose the screw can produce nylon sheathed wire, can satisfy the single injection, double injection, double-layer co-extrusion different technical requirements, etc.

品質(zhì)控制:配備外徑檢測反鎖裝(zhuāng)置,控制産(chǎn)品的外徑、同心度等工(gōng)藝參數,避免因線(xiàn)徑及絕緣厚度誤差,而導緻生産(chǎn)的成本上升。

Quality control: it equipped with outer diameter detection device to control the wire out diameter concentricity other process parameters to avoid the error of wire diameter insulation thickness, which lead to rising costs of production.

·電(diàn)控:進口變頻器+PLC觸摸屏控制

Electric control: imported inverter + PLC touch screen control.

地址:上海市青浦區(qū)白鶴鎮鶴如路185号

技(jì )術支持:遠(yuǎn)亞科(kē)技(jì )